Haris Digital offers wireless production data collection technology, a solution based on a wireless sensor that can distinguish between the "processing" or "stopped" status of a piece of equipment.

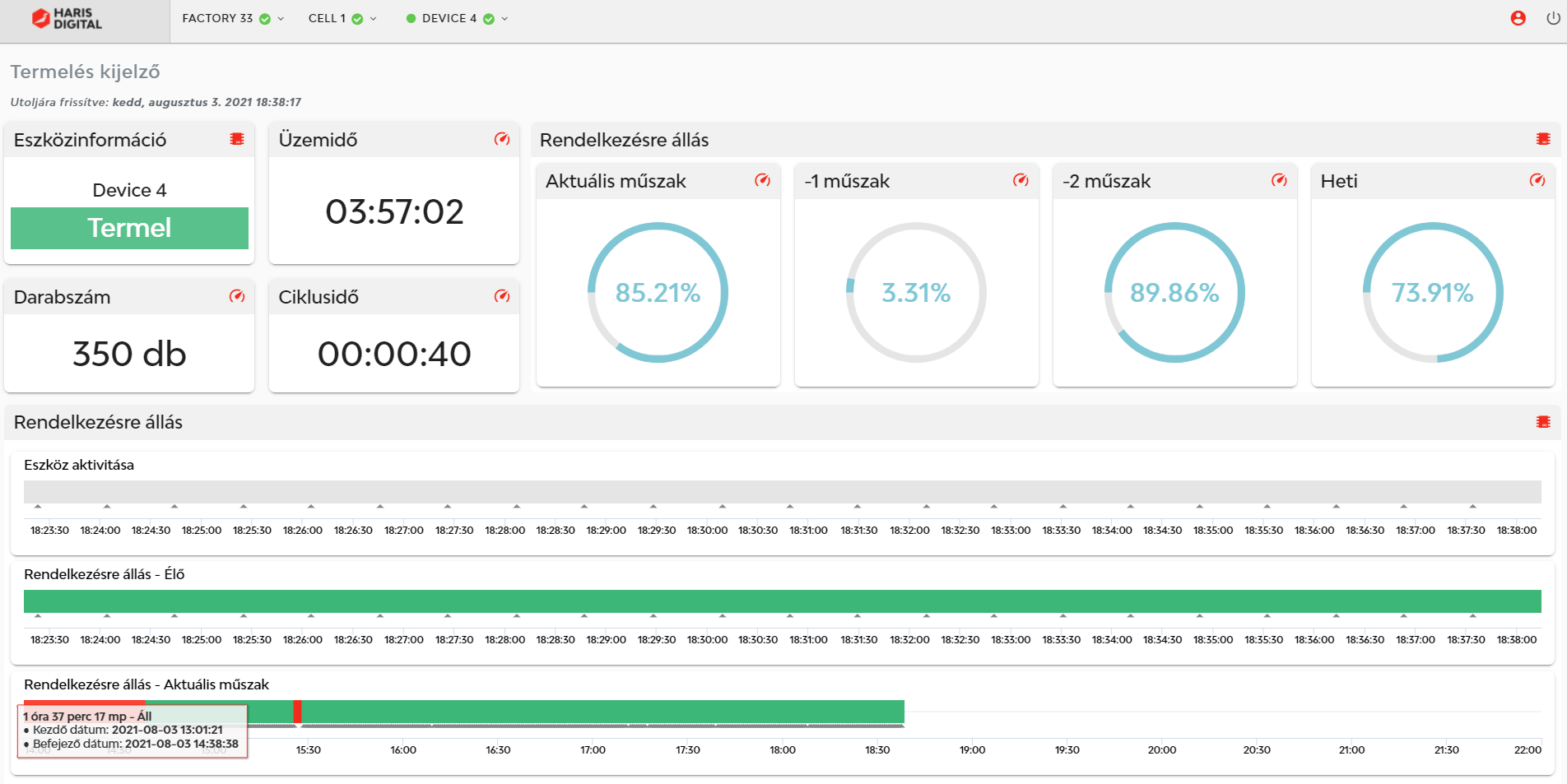

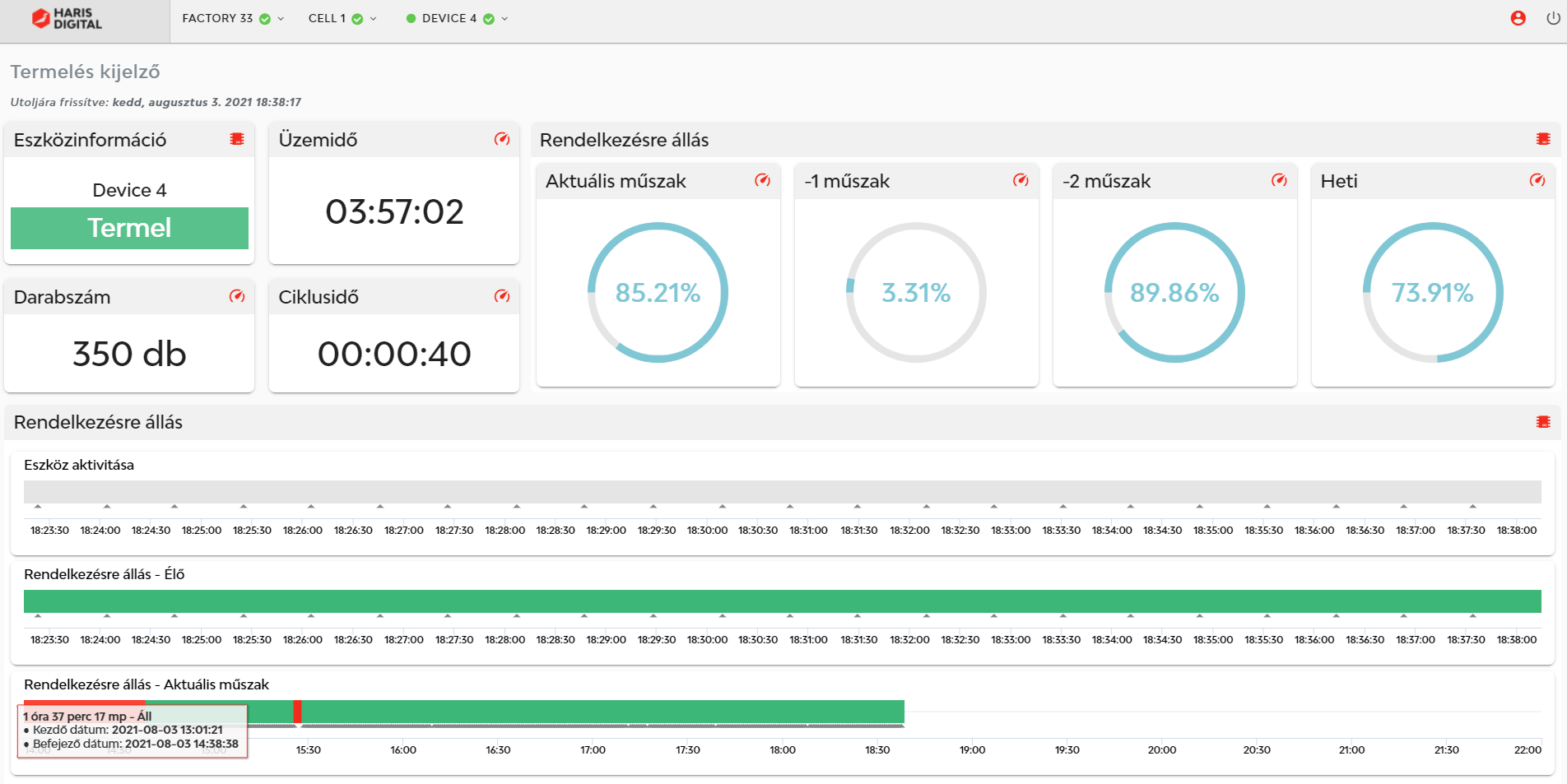

The sensor must be positioned according to the production equipment and the production process and "trained" to respond to the characteristic movement and/or vibration. In this respect, it is a universal solution. The algorithm can then distinguish between the two states. It is important to note that the change of state often characterises only a small part of the process, and from this it is necessary to draw conclusions about the process as a whole and its proper functioning. The detected status is often only an indicator of the process and usually only captures the execution of a certain sub-operation and not the whole process. This method is mostly used to collect data from machines and equipment where wired data collection is not possible or possible but only with difficulty (e.g. it is technically complicated and at the same time less economical) due to the lack of modern control systems. The data thus extracted can be added to the data collection with industrial controls, in order to increase the coverage of the devices covered in data collection in a given plant. The following indicators can be defined from the process of status changes:

■ downtime

■ availability

■ cycle time

■ number of pieces

Haris provides special API's to connect to visualization and reporting systems such as WaMeWo. This is how Indeveyes Technologies and Haris Digital's joint dashboarding system was born, which fits perfectly into the WaMeWo platform in terms of both metrics and visualization. Thanks to this, the WaMeWo dashboarding and reporting product is available as a standalone product for Haris sensors, and we can also offer our customers a hybrid with the full WaMeWo functionality for other types of data collection machines.