“Two things in the world are infinite: the universe and human stupidity. Although I’m not sure about the first.” – Albert Einstein

The above provocative statement by one of the greatest (if not the greatest) genius of the last century is not one we’d like to argue with. But we would much rather argue with the fact that humanity has so often treated (and often still treats) the amount of energy available to us on Earth as infinite. But the amount of energy available to us is finite – and even without Einstein, we can be sure of that…

Energy was also the basis of industrial development

Various sources of energy, relatively easily available in nature, have been used for centuries to make our lives easier. The combustion of fossil fuels (such as coal, oil, natural gas, etc.) has led to breakthroughs that have paved the way for technological – and industrial – development. It has also ensured a comfortable way of life for mankind for a long time. Then, over time, it became clear that not only is the reproducing of fossil fuels not feasible on a human scale, but their use is also extremely damaging to the environment. In addition, an extra factor has arrived in the last few decades: satisfying the hunger of an exponentially growing human population of all kinds requires ever more resources.

We are increasingly feeling the limits of all this on our own skin. Developing alternatives has become unavoidable – if we want to leave a liveable planet for generations to come. Unfortunately, the technologies available do not yet support the optimal use of renewable energy sources, which are the main alternative.

In the short term, we have only one option: we need to make the best use of resources. A series of regional and EU regulations are guiding companies in this direction, with various subsidies and sanctions. We can mention here the mandatory energy metering above 50 kW under the MEKH regulation introduced a few years ago, the EER or the ESG (also known as CSRD), which will be discussed in detail in this article.

Saving energy: easy to say… but not necessarily hard to do!

To achieve the potential savings in production, we need to be able to formulate actions that can be applied while providing a continuous and uninterrupted service to our customers. In other words, we may not be able to switch off our high-consumption machines, for example, during a busy period in the network when it is busy fulfilling a customer order…

Below we will try to provide some tips to overcome this and show how WaMeWo‘s “NRG” module can play a supporting role in these efforts.

The first step is to have or build a metering system that collects energy consumption data for each device with sufficient resolution. The focus will be on electricity consumption, but the approach can be applied with a slight bias to any other energy carrier (e.g. compressed air, water, steam), or in practice, mostly the outputs of devices that draw electricity (compressors, etc.). A wide range of meters are now available on the market, typically with a sampling rate of 15 minutes, based on regulatory compliance, but some types can go beyond this.

[NOTE] It is recommended that when selecting meters, not only the sizing to the nominal consumption should be considered, but also the scalability, the non-destructive installation and the connectivity to the Ethernet-based network.

Some measuring devices support different protocols (M-Bus, Modbus, RS-485, etc.). This is not necessarily a problem, but it is necessary to install data loggers on top of these types of nodes, which can transmit the measured analogue values to the “NRG” module via some modern output (e.g. MQTT). Once the measurement infrastructure is implemented in this way, we are ready to collect and use the measurement data.

In addition to the immediate visualisation of the consumption data for each endpoint, the corresponding CO2 emissions and the costs incurred are also displayed in one single step (thanks to the equivalents that can be defined in the system). Isn’t it a bit more painful to be confronted with energy consumption?!

I see how much we consume, but how can I save?

#1 Cost reduction and energy efficiency

Based on the data, we can make recommendations for optimisation that will reduce energy costs. Savings can quickly contribute to a return on the cost of the metering system.

[NOTE] We can also help you to develop a more optimal energy management strategy by visualising your daily energy use periods on a heat map, making it easy to see which periods are more and less stressful. This is a particularly useful tool for those who do not have a fixed price contract with their energy supplier or who also use renewable energy sources.

#2 Planned Maintenance and Failure Prediction

patterns in machine energy consumption can help you detect when a piece of equipment is becoming inefficient or approaching a failure. This can avoid costly unplanned downtime, further increasing profitability. WaMeWo’s architecture allows for the collection and visualisation of measurement data from the system in samples of up to seconds (if the meter is capable of it). This way, the distortion of the patterns can also indicate an anomaly.

#3 More accurate cost allocation and pricing

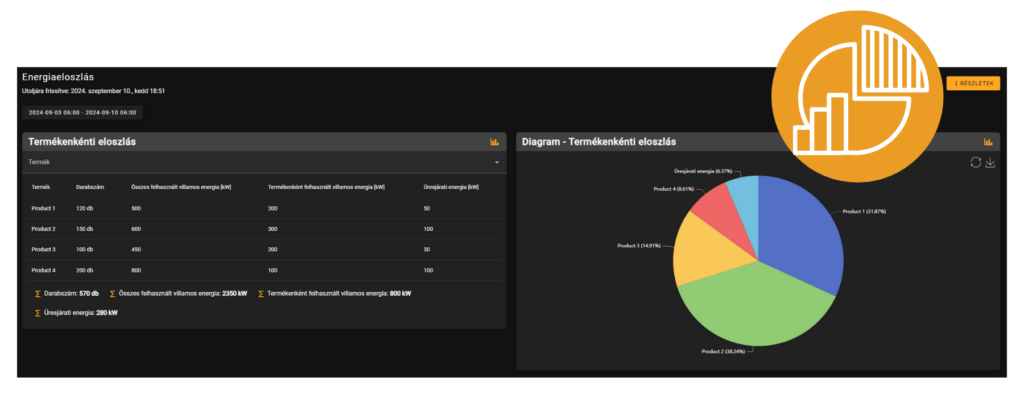

by monitoring energy consumption per machine, the real costs of each product or production process can be accurately determined. This will help you

- reduce production costs,

- optimise pricing,

- and in addition, the ESG reporting obligations that will soon be introduced for large companies and SMEs will require it!

WaMeWo (when used in combination with the OEE and NRG modules) automatically calculates the cost allocation per product.

#4 Environmental awareness and compliance

In many industries, there is a growing demand for energy efficient operations, both due to legislation and sustainability goals (ESG). Continuous monitoring of energy consumption helps companies to comply with regulations and reduce their carbon footprint, which can be an important competitive advantage in addition to meeting customer expectations.

Numbers don’t lie: return on energy efficiency investments

Behind every development or investment, it is necessary to set up some possible payback scenario. Let’s look at a simple example! The figures used below are of order of magnitude, and can vary significantly depending on the different environmental variables.

1. Collecting basic data

| Current annual energy consumption | Estimate or retrieve the current annual energy consumption (kWh). |

| Average electricity cost | e.g. € 0.1/kWh (this varies depending on current energy prices) |

| NRG module cost | This could be a one-off investment or a licence fee (e.g. €10,000). |

| Expected reduction in energy consumption | A successful project can deliver energy savings of up to 5-15%. |

| Reduction in maintenance costs | If the NRG module helps to predict failures, further savings can be made. |

2. Calculating ROI

An example:

| Annual energy consumption | 1 000 000 kWh |

| Average electricity cost | 0.1 € / kWh |

| Annual energy cost | 100 000 € (1 000 000 kWh × 0.1 €) |

| Expected savings | For a 10% reduction in energy consumption, the annual savings will be 10 000 € |

| Investment cost of NRG module | 10 000 € |

ROI formula:

- ROI = (Annual Savings / Investment Cost) × 100

- ROI = (€10 000 / €10 000) × 100 = 100%

This means that the system can pay for itself within one year and generate a profit every year thereafter!

3. Extended calculations

Maintenance savings. If the savings from maintenance are taken into account (e.g. €5,000 per year by optimising planned maintenance), the total annual savings could be €15,000.This further accelerates the payback.

Increased payback – in this case:

- ROI = (15 000 € / 10 000 €) × 100 = 150%

- The system will pay for itself in less than 1 year and can generate annual savings of €15,000 in the following years.

4. Other factors

For higher volumes: if more machines are connected to the system, savings will scale.

Other costs: the cost of maintenance or upgrading can be taken into account, but the focus is on significantly reducing electricity costs.

Energy efficiency grants (EDF)

Thanks to the Energy Efficiency Obligation Scheme (EEO), you can earn money by improving efficiency (OEE) or saving energy. This scheme, which has already been successfully implemented in 16 countries across Europe, allows companies (end-users) that can demonstrate that they are reducing their energy consumption to receive non-repayable subsidies.

Such a certified energy efficiency investment by an end-user could be, for example, the replacement of an old, inefficiently operating machinery line with a more modern one, the energy modernisation of an industrial facility such as insulation, modernisation of a compressed air system or heating system, renovation of buildings, etc. The beneficiaries of the obligation scheme will be domestic business and residential end-users, while maintaining stability in residential energy prices.

Verification of such investments is essential, as the support is conditional on accurate and measurable proof of energy savings. In this area, WaMeWo NRG offers a solution as an “EKR-ready” monitoring system that ensures the collection and tracking of verified data.

We can also support energy efficiency projects with financing (e.g. ESCO), so you don’t have to deal with the high costs of the investment or involve an external lender or credit institution. By taking advantage of these opportunities, investments start to generate money sooner than the costs are incurred. The financial process is thus self-reinforcing, as the energy costs saved can be used in other areas or even for further improvements as soon as possible.

Ecorisk Ltd. is a reliable partner for the implementation of EER and energy efficiency projects.

Take aways

The fate of future generations is in our hands, and we must now lead the way towards sustainability and minimised environmental impact. To do this, we need to measure the use of different energy characteristics in production with as much resolution as possible, eliminate the losses identified as soon as possible and do our utmost to make the switch to renewable energy sources as large as possible.

We are committed to implementing WaMeWo’s discovery skills into the energy ecosystem (from enclosure to hardware to software to support), and to helping you gain business benefits from savings and accurate sustainability reporting by implementing full-scale EER or ESG projects.

What is this series of articles about?

This series of articles has been compiled by our team in order to provide both technological and business know-how for professionals involved in the digitalisation of the industrial sector. The chapters follow two guiding principles:

- exploring the reasons behind the manufacturing digitisation software technologies used and

- demonstrating their potential for business use.

We trust that our content will provoke constructive professional discourse. We welcome your feedback, opinions or questions on info@indeveyes.com or our social media platforms!