Nowadays, i4.0/SmartFactory software solutions are becoming more and more common toons for increasing efficiency. These include WaMeWo, which fuses isolated production units into an integrated, automated and optimised high-efficiency production process.

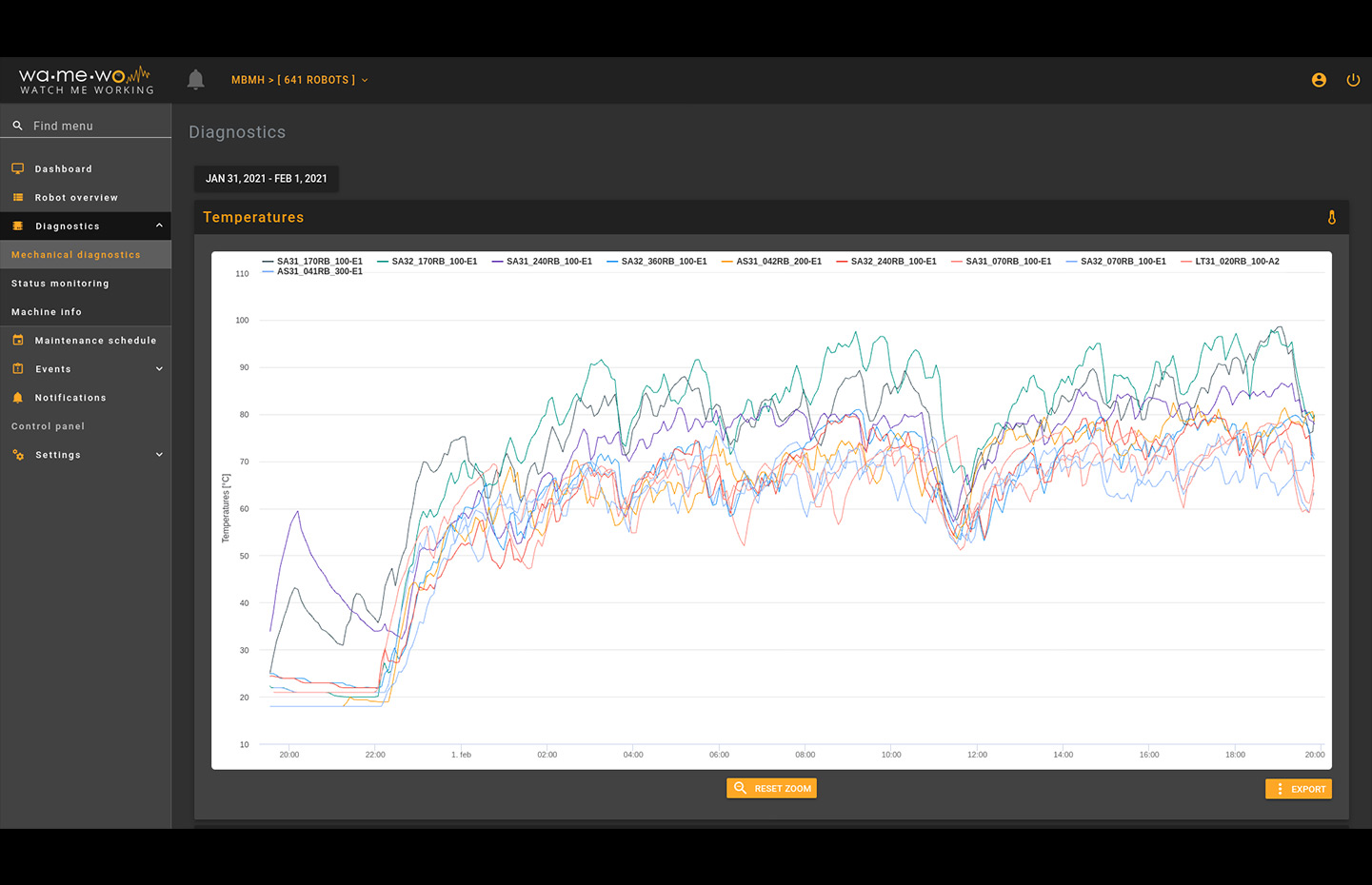

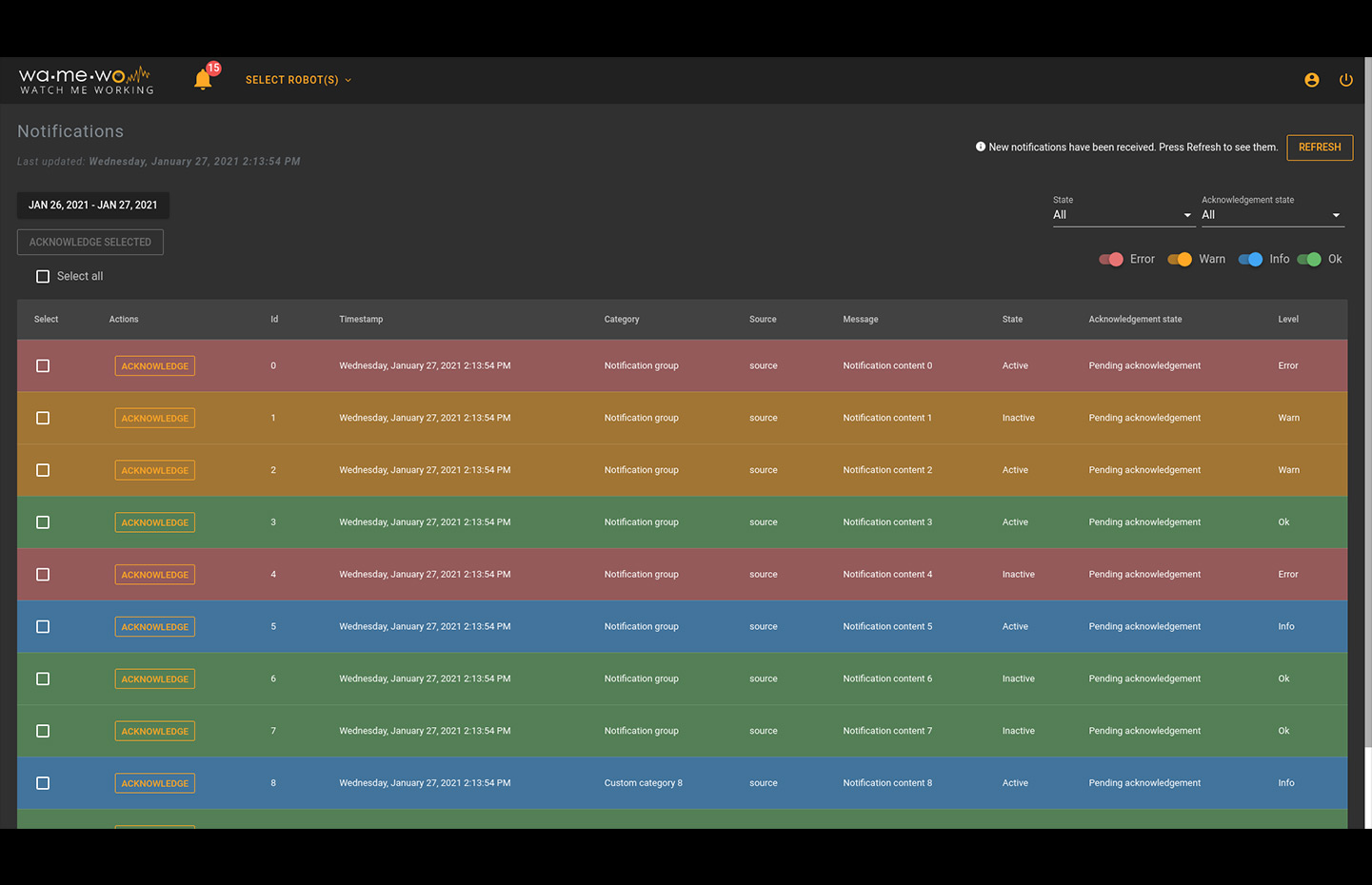

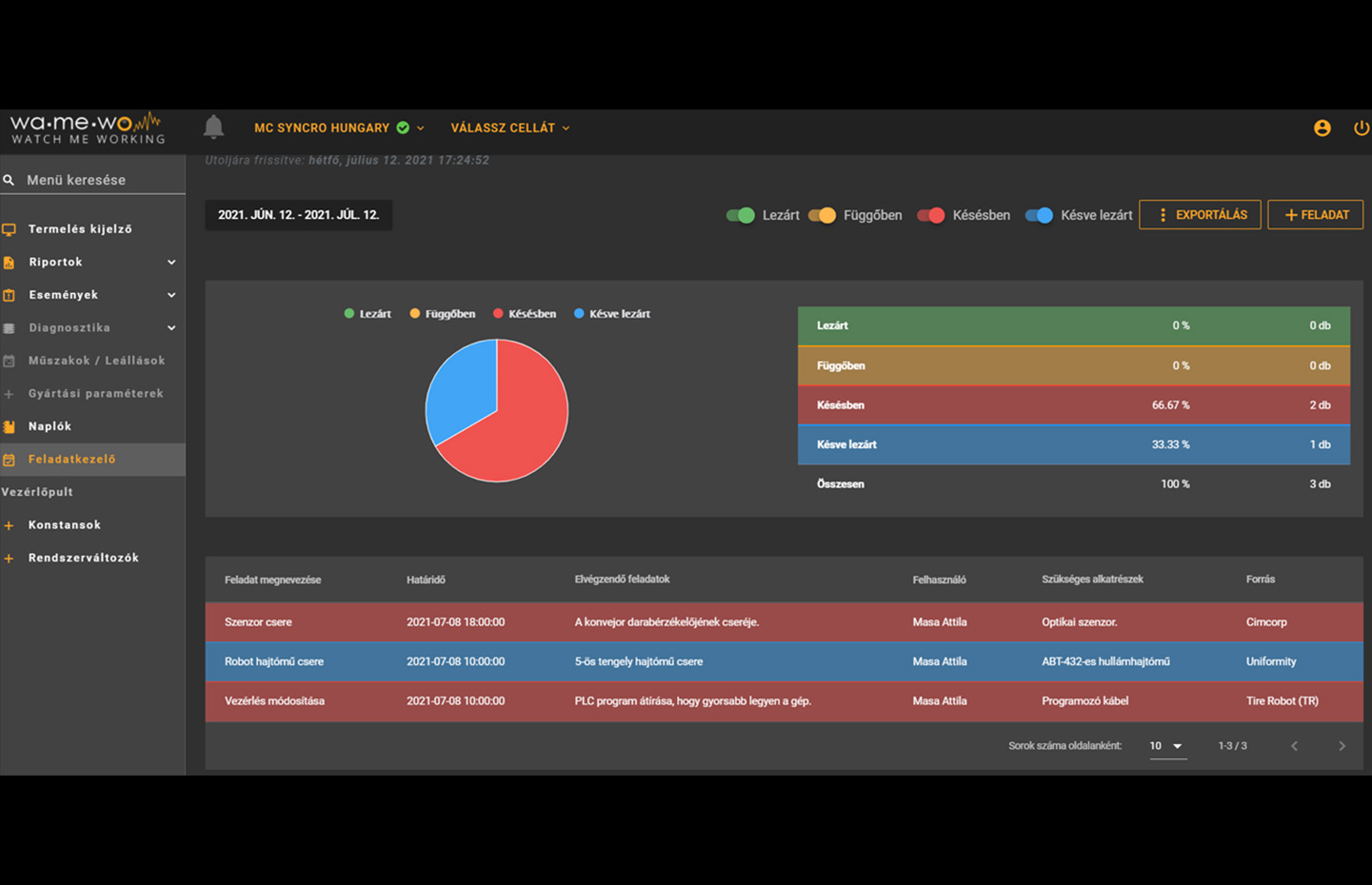

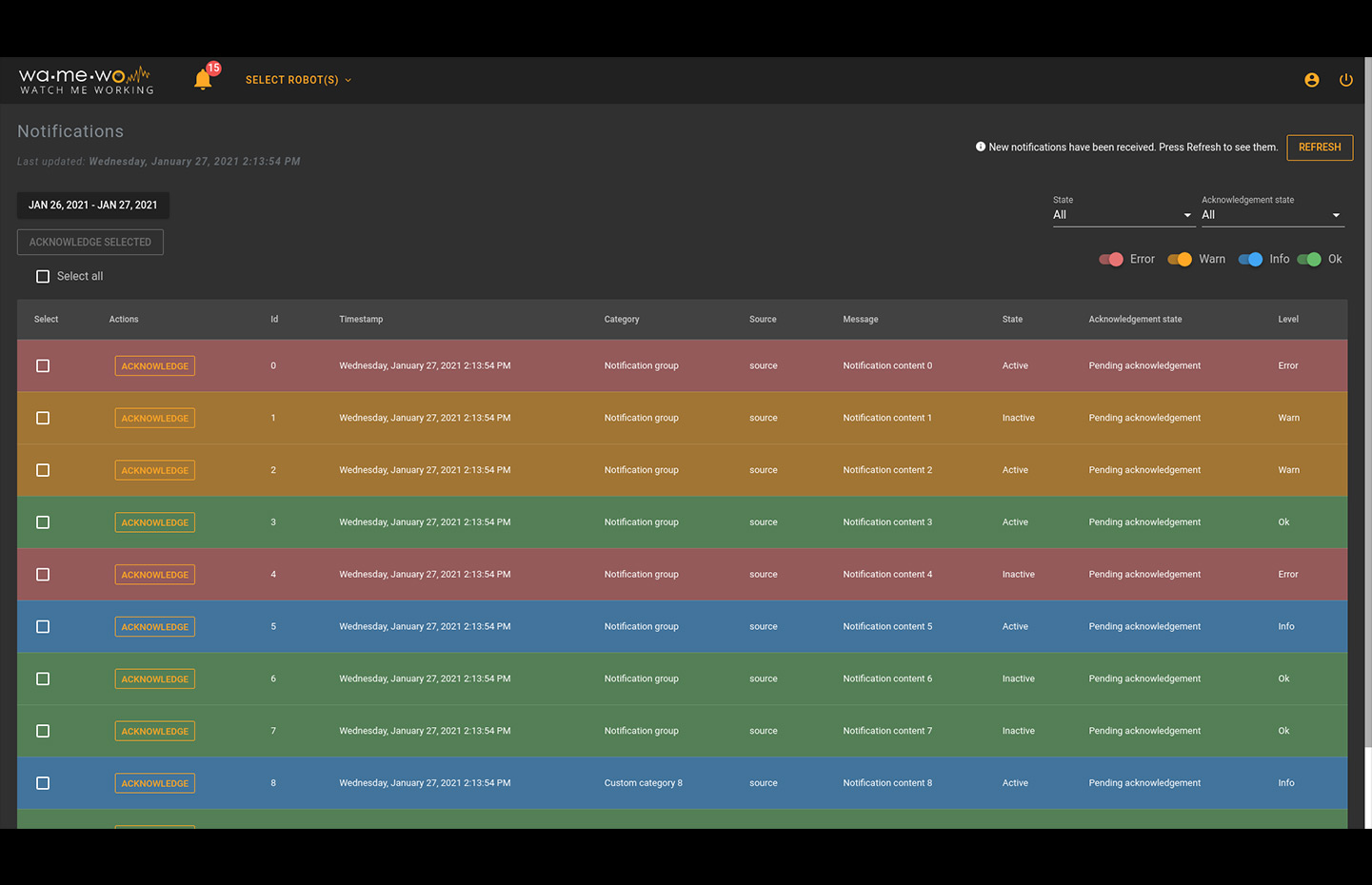

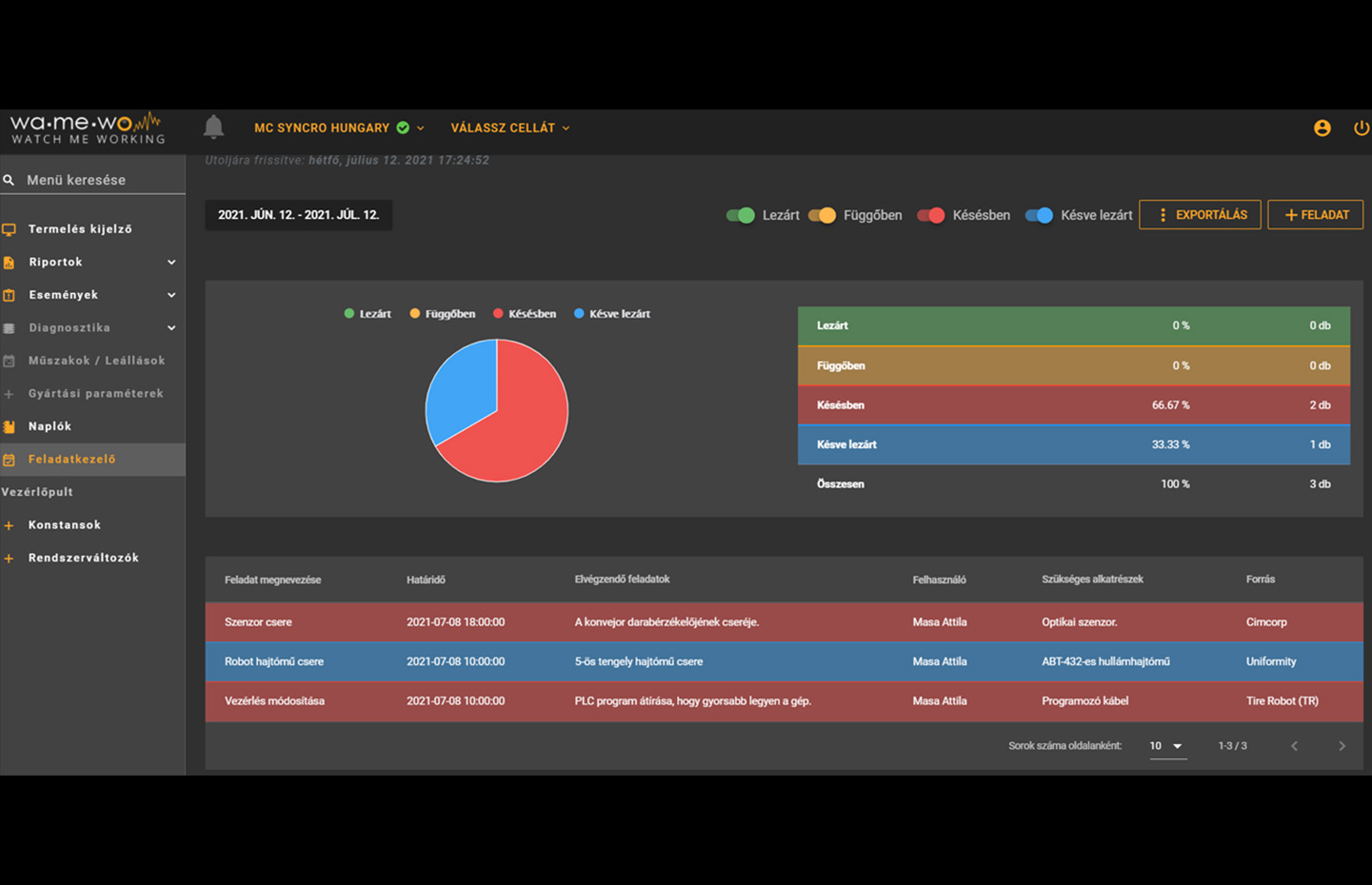

WaMeWo (Watch Me Working) responds to the cyber-physical hunger of today’s manufacturing industry: providing real-time, remote monitoring and historical diagnostics of manufacturing machines with various controllers (e.g. industrial robot, PLC) through non-invasive software technology solutions. After aggregating and analyzing the collected data, we offer versatile functionality and useful information that cover the widest range of users in the factory, from maintenance to the top management. All with one single turn-key modular system that can be flexibly customized and expanded to suit anyone’s needs. - A cost effective solution to get started with digital manufacturing - Provides a comprehensive view of production events and highlights loss centers - Gives accurate, real time OEE value feedback, thus supporting rapid intervention and efficiency gains - Features special diagnostic modules to focus on future failure events that can be prevented by preventive maintenance - With an extensive functionality it supports maintenance, operation and management in their daily work WaMeWo features: >> Telemetry Able to collect data from various sources (e.g. industrial controls, PLCs, robots, etc.) and pre-format / aggregate and send to the WaMeWo IIoT platform. >> Labour interaction On devices installed on a production line (HMI), the employee can enter various data (downtime registration), and even dedicated feedback can be implemented. >> OEE Measuring the Overall Equipment Efficiency of devices and areas (measure both in real time and historically) to visualize and explore the focal points of production losses. >> Robot diagnostics Collects and analyzes operational data from industrial robotic arms, performs analytics to help prevent errors, thus supporting predictive maintenance. >> Events It collects, visualizes and analyzes error signals from different data sources (machine / human) to reveal bottlenecks and indicate alerts in case of malfunctions. >> Self-service dashboarding The metrics collected by the platform allow the user to create custom dashboards and reports. To do this, you can select several types of components (chart, table, thumbnail, etc.) >> Predictive maintenance To reduce machine failure, we need to be able to accurately predict when that failure might occur and have corrective actions in place. This can assist in major cost savings and greater availability. >> Task management Based on the system signals, we can generate various tasks (for example machine maintenance) for users, with which we can even monitor the efficiency of the work of workers. >> Quality assurance We have our own unique solution that allows us to compare the coordinates in the model space with robot coordinates so we can check if a technology is in the right position. >> Alerting Collected metrics can be used to create an email or inapp alert for a data point (e.q. treshold check, deadman check) so the user can be notified of events even when not logged in. >> Energy monitoring It receives and stores the data of energy consumption meters (electrical, pneumatic, etc.) connected to telemetry, and prepares statements and reports from them. >> Production planning For OEE it is necessary to define standards, manufacturing, and shift planning. If this is not available from another system, this design can be done on this interface. For more information, visit https://wamewo.com/

Our customizable production monitoring system that helps you answer i4 challenges